We are better together.

With combined skills, pooled knowledge, and strong teams.

Pretreatment rethought: EcoProWet PT

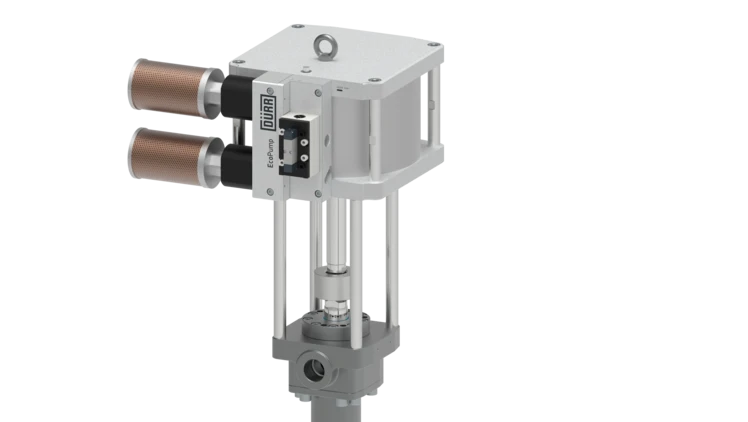

The EcoSupply2 Core delivers significant time savings on assembly, commissioning, and documentation

The EcoBell cost-effectively paints plastic parts with minimal material consumption

Dürr and Mercedes-Benz

Strategic partnership for sustainable painting technology

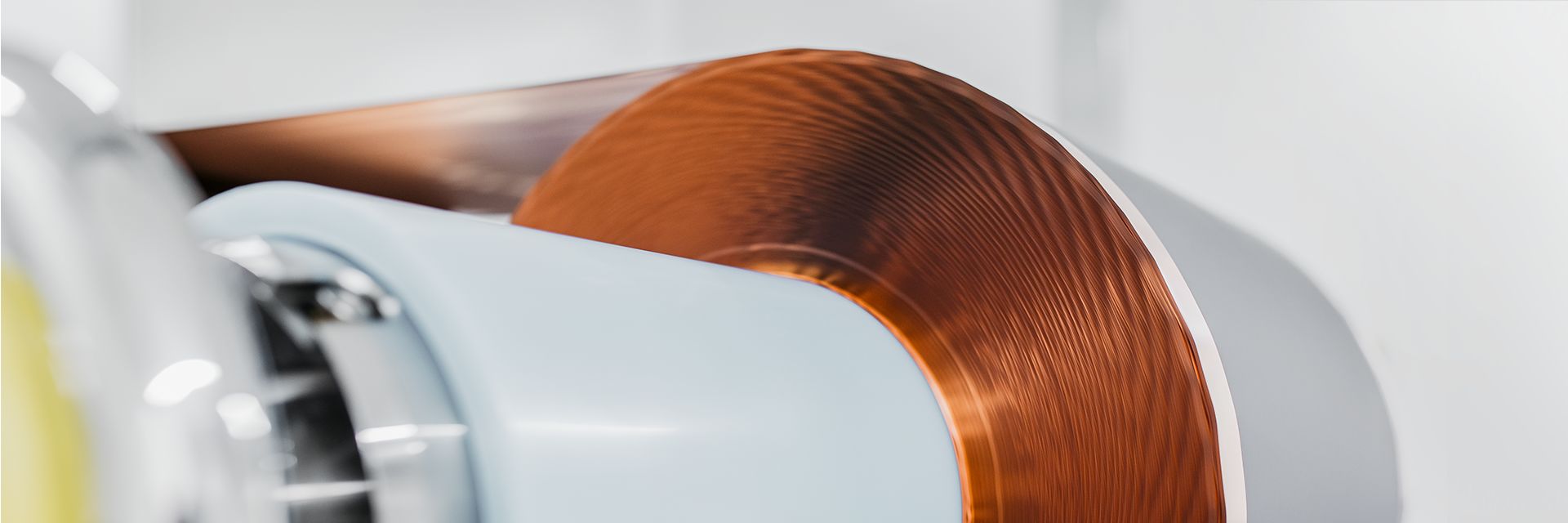

EcoBell4 Rotary atomizer

From green to red to yellow to blue.

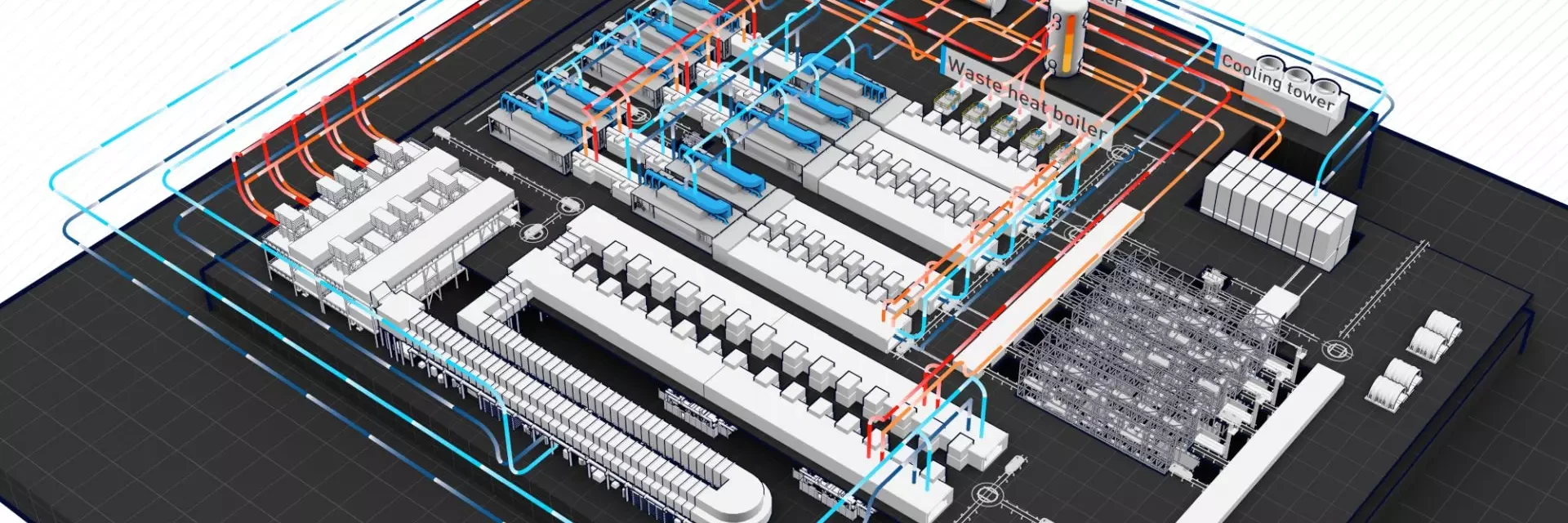

EcoQPower

takes paint shop energy efficiency to a new level

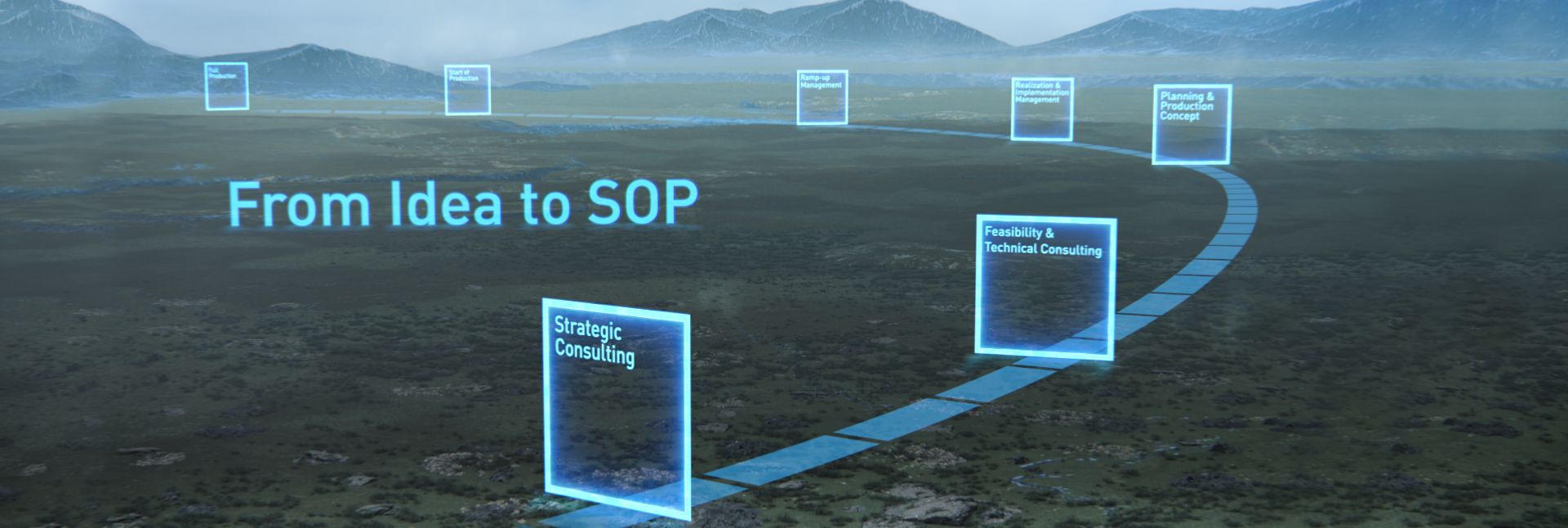

Electrode manufacturing

Highest quality from R&D to mass production

Air Pollution Control Experts

World’s largest product array

Using digital helpers in a targeted manner

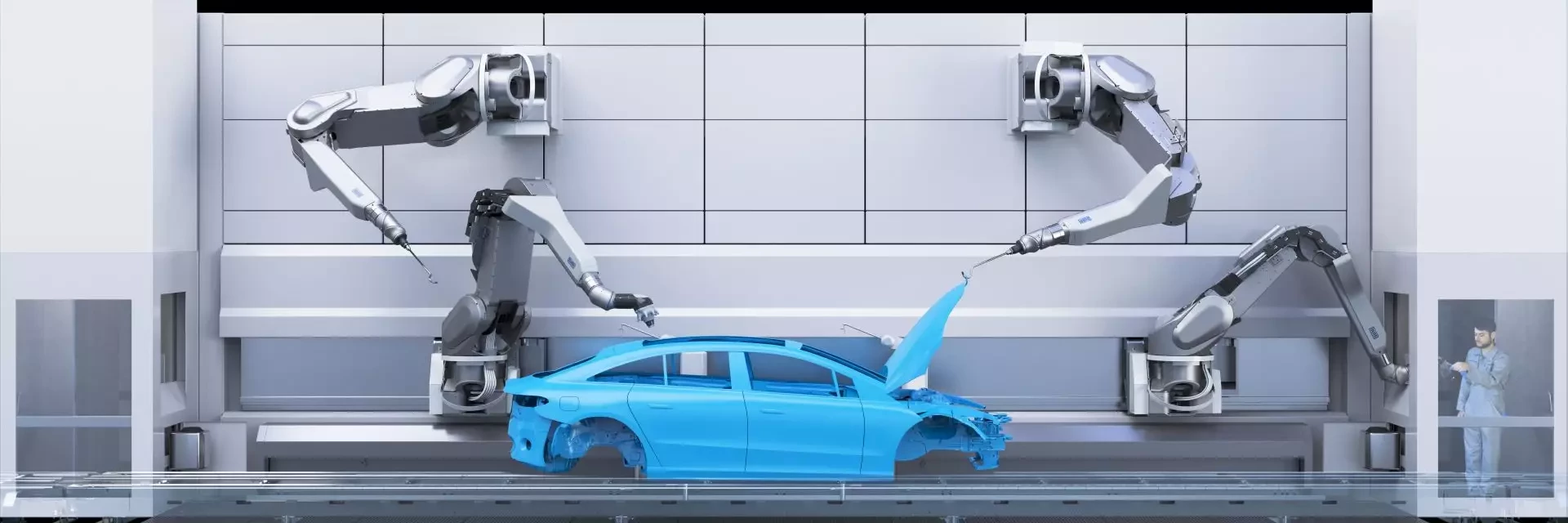

Dürr’s NEXT.assembly provides customers around the world with processes and technologies for optimized final assembly solutions.

Leading in Production Efficiency

Dürr Systems AG is part of the Dürr Group, one of the world's leading mechanical and plant engineering firms with outstanding expertise in the fields of automation and digitization.

The Dürr Group is active on the market with the three main brands Dürr, Schenck, and HOMAG. The long-established brand Dürr has been a byword for continuous innovation since 1896, with a wide range of products in robot, process, and assembly technology for all areas of vehicle production, focusing on painting and final assembly lines.

Dürr also offers painting technology for general industry. In the field of environmental technology, Dürr supplies efficient systems for exhaust air purification, for increasing the efficiency of production processes, and for sound insulation technology for a wide range of industries. Smart automatic and supervisory control systems and an efficient service offering complete the portfolio.

At a glance

Career at Dürr

Discover the future and shape it at Dürr. Find job opportunities worldwide!

Events

Locations | Contact us!

Here you can activate a map service. This results in a transmission of your data (e.g. IP address) to the respective provider, as explained in our data protection .

Agree

- Dürr represented by: BEMAQ S.A.Panamericana Colectora Este 2011, Oficina 104

B1609JVB Boulogne, Prov. De Buenos Aires

Argentina - Dürr Brasil Ltda.Rua Arnaldo Magniccaro, 500

CEP 04691-903 São Paulo - SP

Brazil - Verind Brasil Serviços & Soluções LtdaAv. Amazonas 1446

32600-324 Brasileia - Betim - MG

Brazil - Dürr represented by: AGRAMKOW do Brasil Ltda.Alameda Ezequiel Mantoanelli 405, Jardim Panorama

13340-350 Indaiatuba

Brazil - Durr Systems Canada, Inc.611 Kumpf Drive, Suite 100

N2V 1K8 Waterloo, Ontario

Canada - Dürr Paintshop Systems Engineering (Shanghai) Co., Ltd.No.665 YingShun Road, Qingpu Industrial Park

201799 Shanghai

China - Megtec Systems (Shanghai) Ltd.No. 125, Lane 1190, Jiujing Road Jiuting Town, Songjiang District

201615 Shanghai

China - Dürr represented by: Schenck Shanghai Machinery Corp. Ltd., Beijing BranchNo. 1111, Fengxiang Rd. Baoshan district

200444 Shanghai

China - Dürr represented by: Schenck Shanghai Machinery Corp. Ltd., Beijing BranchRoom 1111, SciTech Tower, No. 22, JianGuoMenWai Avenue, Chaoyang District

100004 Beijing

China - teamtechnik Production TechnologyBuilding 8B, Xin Xing Industrial Park II, No.78 Xing Lin Street, Suzhou Industrial Park

215026 Suzhou

China - Dürr represented by: Kodama s.r.o.Pod. Postou 102

190 15 Praha 9

Czechia - Dürr represented by: AGRAMKOW Fluid Systems A/SAugustenborg Landevej 19

6400 Sønderborg

Denmark - Dürr represented by: Heavy Industries Services Co. 'HISCO'Building 15 Block 1149, 15 Salah Zaki Street

11361 Sheraton Heliopolis/Cairo

Egypt - Dürr SystemsImmeuble Gaïa - 9 Parc Ariane Boulevard des Chênes

78280 Guyancourt

France - Datatechnic S.A.S.5 Impasse du Stade

88390 Uxegney

France - Dürr SystemsZ.I. des Malines 32 rue des Malines

91090 Lisses

France - Dürr AktiengesellschaftCarl-Benz-Str. 34

74321 Bietigheim-Bissingen

Germany - Dürr Systems AGCarl-Benz-Str. 34

74321 Bietigheim-Bissingen

Germany - iTAC Software AGAubachstr. 24

56410 Montabaur

Germany - Dürr Assembly Products GmbHKöllner Str. 122 - 128

66346 Püttlingen

Germany - Dürr represented by: Schenck RoTec GmbHLandwehrstraße 55

64293 Darmstadt

Germany - teamtechnik Maschinen und Anlagen GmbHPlanckstr. 40

71691 Freiberg (Neckar)

Germany - teamtechnik Automation GmbHHeinrich-Hertz-Straße 1

71642 Ludwigsburg

Germany - Dualis GmbH IT SolutionBreitscheidstraße 36

01237 Dresden

Germany - Dürr India Private Ltd.471, Prestige Polygon, Anna Salai

600 035, Nandanam, Chennai

India - Megtec Systems India Pvt. Ltd.Plot No. 6/5, CTS No 8/5 Erandawana Near Nal-Stop, Karve Rd. Behind Saraswat Bank

411004 Pune

India - Universal Acoustic & Emission Technologies Pvt. Ltd.4 Anmol Pride, Survey No. 270/1/16, Baner Road

411045 Pune

India - Dürr represented by: Schenck RoTec India LimitedA-5, Sector 81 Phase - II

201 305 Noida

India - Dürr India Private Ltd.Plot No. 6/5, CTS No 8/5 Erandawana, Karve Rd. Behind Saraswat Bank

411004 Pune, Maharastra

India - PT Dürr Systems IndonesiaPlaza Summarecon Bekasi, 8th Floor, Unit 801, Jalan Boulevard Ahmad Yani, Blok KA No.1

17142 Bekasi Utara

Indonesia - Verind S.p.a.Via Papa Giovanni XXIII, 25/29

20053 Rodano (MI)

Italy - Olpidürr S.p.A.Via G. Pascoli 14 – I

20054 Novegro di Segrate

Italy - Verind MelfiSP48 Zona Industriale San Nicola

85025 Melfi (PZ)

Italy - Dürr Japan K.K2-14-6 Sakae-cho

273-0018 Funabashi, Chiba

Japan - Dürr Korea Inc.20F., D-Cube City 662, Gyeongin-ro, Guro-gu

08209 Seoul

Korea, Republic of - Dürr Korea Inc.9, Maegoksaneop, Buk-gu

44222 Ulsan

Korea, Republic of - Dürr Systems Malaysia Sdn. Bhd.4, Jalan SS 13/4, Subang Jaya Industrial Estate,

47500 Subang Jaya, Selangor

Malaysia - Dürr de México S.A de C.V.Avenida La Noria No. 168, Parque Industrial Querétaro

76220 Querétaro

Mexico - Durr Universal S. de R.L. de C.V.Av. Mantenimiento No. 130 Zona Industrial

78395 San Luis Potosi

Mexico - Dürr represented by: Carl Schenck Machines en Installat. B.V.Schiedamsedijk 81 a

3011EM Rotterdam

Netherlands - OOO DÜRR SYSTEMS RUSKrasnoproletarskaya str.16 Building 2

127473 Moscow

Russian Federation - Dürr represented by: AGRAMKOW ASIA PACIFIC PTE LTD.100G Pasir Panjang Road- Interlocal Center

118523 Singapore

Singapore - Dürr represented by: DS - Slovakia, s.r.o Business Office BratislaveMedved'ovej 19

851 04 Bratislava

Slovakia - Dürr Africa (Pty) Ltd.33 Roshan Road Framesby

6045 Port Elizabeth

South Africa - Dürr Systems Spain S.A.U.C/ Zuatzu 8, Planta 2ª Parque Empresarial Zuatzu - Edificio Oria

20018 Donostia San Sebastián

Spain - Dürr Systems Spain, S.A.U.C/ Antonio Machado 78-80, Planta baja; Viladecans Business Park - Edificio Australia

08840 Viladecans

Spain - Megtec Systems ABOlskroksgatan 30, Box 6106

40060 Göteborg

Sweden - Dürr represented by: Proclima Processervice ABPostiljonvägen 6

432 92 Varberg

Sweden - Dürr represented by: Turn Luckily Technology Co. Ltd.5th Floor, 93 Hsin-Sheng South Road Sec.1

10626 Taipei

Taiwan, Province of China - Dürr (Thailand) Co., Ltd.631 Media Gallery Building, 2nd Floor, Nonsee Rd., Chongnonsee, Yannawa

10120 Bangkok

Thailand - Dürr represented by: Scalar Technology Co. Ltd.128/73 Phyathai Plaza Building, 7th floor, Phyathai Rd. Thung-Phyathai

10400 Bangkok

Thailand - Dürr Systems Ltd. SirketiSahil Mahallesi D-130 Karayolu Caddesi No: 45/4

41030 Basiskele / Kocaeli

Türkiye - Dürr represented by: Dürr Systems – Schenck Branch OfficeHukukçular Towers A Blok No:35

34758 Kartal / Istanbul

Türkiye - Dürr Limited - WarringtonLakeview 600 Lakeside Drive

WA1 1RW Warrington

United Kingdom - Dürr Limited - LeicestershireBarleyfield Hinckley

LE10 1YE Leicestershire

United Kingdom - Dürr represented by: AGRAMKOW Fluid SystemsWindmill House Industrial Estate, Sutton Road

Y032 2RA Wigginton, York

United Kingdom - Dürr represented by: Schenck LimitedBroxell Close

CV34 5QF Warwick

United Kingdom - Dürr Systems, Inc.26801 Northwestern Highway

48033 Southfield, MI

United States - Dürr Systems, Inc. - De Pere830 Prosper Street

54115 De Pere, WI

United States - Durr Universal, Inc.1925 Highway 51 - 138

53589 Stoughton, WI

United States - Dürr represented by: Schenck USA Corporation26801 Northwestern Highway

MI 48033 Southfield

United States - teamtechnik Corporation5155 Sugarloaf Parkway Unit O

GA 30043 Lawrenceville

United States - Dürr Systems, Inc. - Ford BlueOval City

- Durr Vietnam Co., Ltd.Room LA.02-04, 2nd Floor, Block A, Lexington Residence Building, No. 67 Mai Chi Tho Street, An Phu Ward, District 2

700000 Ho Chi Minh City

Viet Nam